What is the EN 374 standard?

The EN ISO 374standard specify the test methods for gloves intended to protect a user against an extensive list of chemicals and microorganisms subject to such exposure.

Contact with high risk chemicals can cause serious harm to personal health and the environment.

- EN ISO 374 is divided into five parts, which include:

- EN 374-1:2016+A1:2018 Terminology and performance requirements for chemical risks

- EN 374-2:2014 Determination of Resistance to Penetration

- EN 16523-1:2015+A1:2018 which replaced EN 374-3:2003 Determination of Resistance to Permeation by Chemicals

- EN 374-4:2019 Determination of Resistance to Degradation by Chemicals

- EN 374-5:2016 Terminology and Performance Requirements for Micro-Organism Risks

Chemical-resistant gloves complying with EN374 shall be tested against parts 1, 2, 3 and 4 with EN7374-5 being an optional standard. The following three tests shall be performed:

1. Determination of Resistance to Penetration (EN 374-2:2014)

This test is necessary and must pass to ensure the glove material offers an effective barrier to chemicals, water and micro-organisms. A water and air leak test is carried out to check for any pin holes or potential leaks.

2. Determination of Resistance to Permeation by Chemicals (EN 16523-1:2015+A1:2018)

Permeation refers to the process of liquids and gases, passing through a glove’s material at a molecular level. Chemicals may be able to pass through the glove without there being any visible changes, whilst still coming into contact with the end user’s skin. The EN16523-1 standard measures the effectiveness of a glove’s barrier against a liquid challenge chemical that is in continuous contact with the material. It is used to determine a breakthrough time; ie how quickly the liquid permeates through the material. The performance levels according to the breakthrough time for each chemical tested are classified from 0 to 6.

3. Determination of Resistance to Degradation by Chemicals (EN 374-4:2019)

Any gloves claiming chemical protection must be tested against this standard. The degradation test gives the end users an idea of how the glove physically reacts and gives a measure of the integrity of the material after continuous contact with the challenge chemical. The puncture strength of the material before and after chemical exposure is determined and percentage change in strength is reported alongside the chemical permeation data. Changes in the physical properties of a glove caused by the chemical may include flaking, swelling, shrinking, disintegration, colour change, hardening, softening, etc. If the properties of the glove after exposure to a chemical have been significantly affected, the ability to protect the wearer may be compromised.

EN 374 pictograms

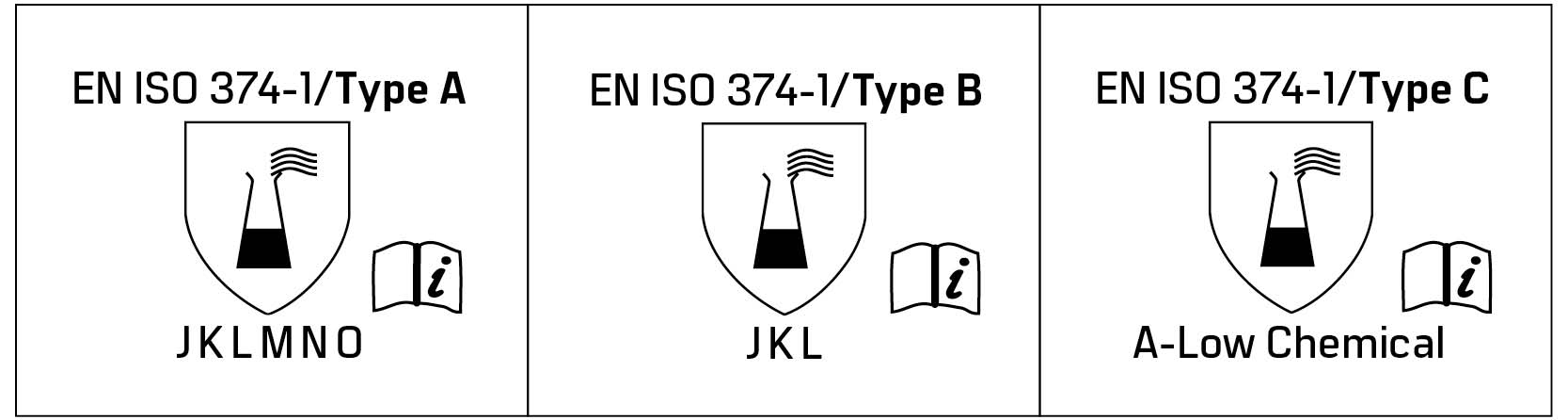

Gloves are categorised as Type A, Type B or Type C based on the number of chemicals they protect against and the performance level they achieve.

The following pictograms are used to outline the three types of classification and are found on the glove, user information sheets and conformity statements:

Type A: Protective glove with permeation resistance of at least 30 minutes each for at least 6 test chemicals.

Type B: Protective glove with permeation resistance of at least 30 minutes each for at least 3 test chemicals.

Type C: Protective glove with permeation resistance of at least 10 minutes for at least 1 test chemical. The tested chemical code followed by the phrase “Low Chemical” is recommended for this pictogram,.

The EN374 Chemical Resistance Guide

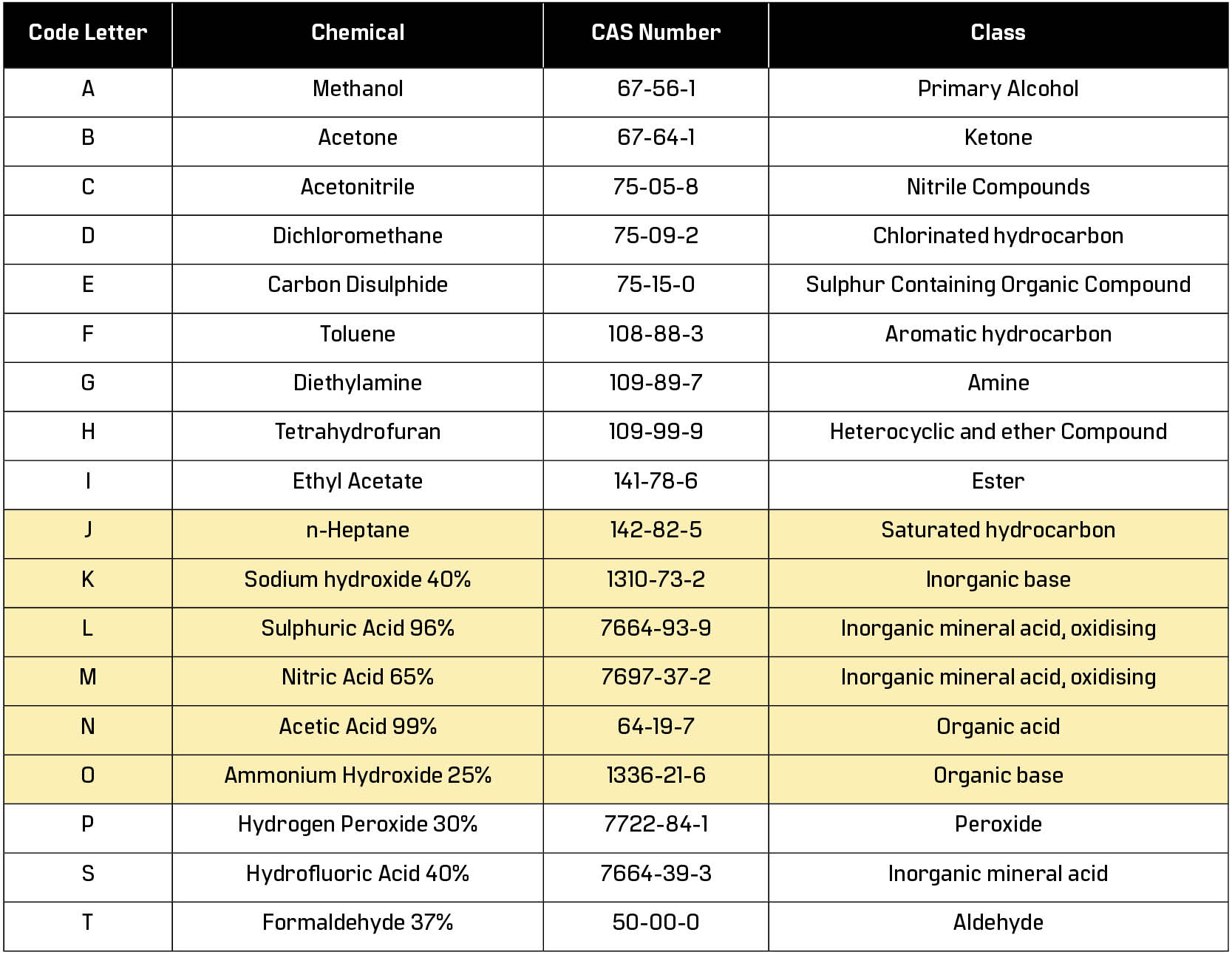

The following is a list of the 18 hazardous chemicals as specified in ISO 374-1:2016+A1:2018 and their correlating letters required in the pictograms:

Protective gloves against microorganisms

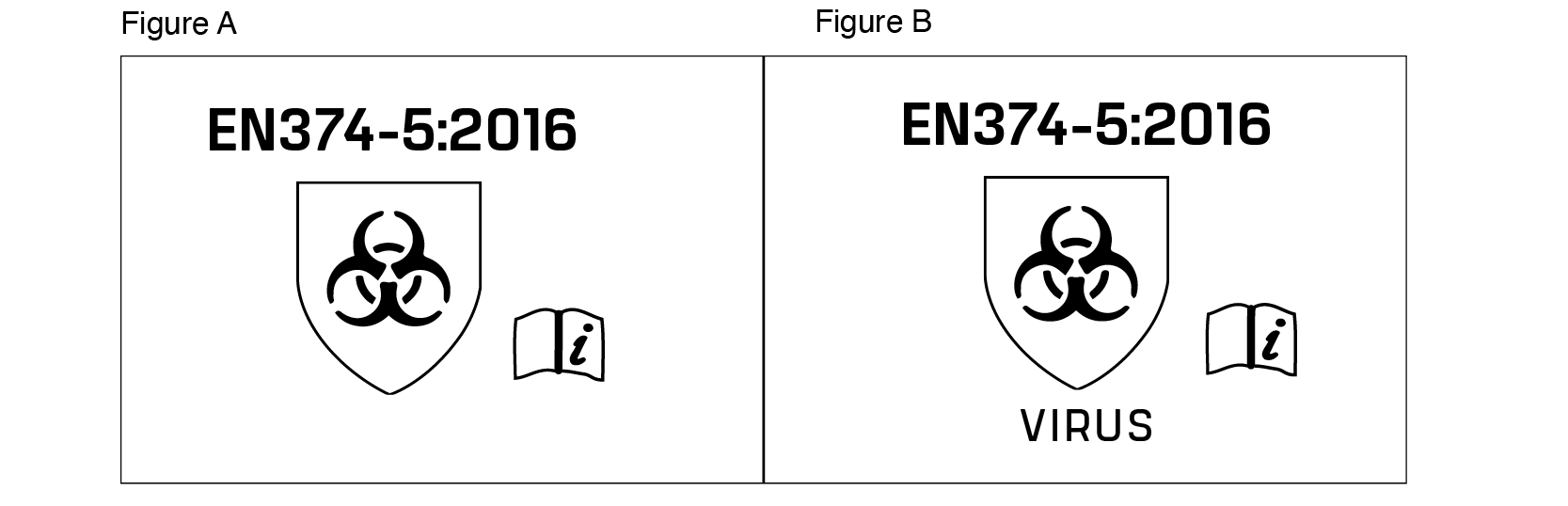

Where gloves require additional protection against viruses, bacteria and fungi, they shall be tested against the EN374-5:2016 standard and where gloves claim protection from viruses, additional testing to ISO 16604:2004 is carried out. Gloves shall also pass the penetration tests in EN374-2:2014.

There are two classifications:

- Protection against bacteria and fungi

- Protection against viruses, bacteria, and fungi

Gloves claiming for protection against bacteria and fungi shall carry the following warnings and pictogram (first image).

The following cautions and pictogram (second image) must be attached to a glove that claims to be resistant to bacteria, fungi, and viruses.

Why choose EN374 certified gloves?

Where end users need protection against chemical hazards, selecting a product that has been certified to EN374 will reassure them that the product has undergone a range of meticulous test methods ensuring the resistance they require. Products should be tested by an ISO 17025 facility and certified by an independent notified body, ensuring the products comply to national standards,